Wide, shallow taper, self-centering design for use in through-bored components with extremely high torque and/or bending requirements. Mounted component remains fixed axially during installation.

View Catalog Page

View Catalog Page

Unit of Measure

Specifications

Shaft Size |

N/A 2 7/8 in |

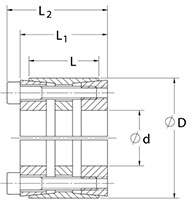

d |

N/A 2.875 in |

D |

N/A 4.331 in |

L |

N/A 2.756 in |

L1 |

N/A 3.150 in |

L2 |

N/A 3.543 in |

Mt |

N/A 9,105 ft-lbs |

Fax |

N/A 76,008 lbs.F |

Ps |

N/A 31808 psi |

Ph |

N/A 21116 psi |

| DN1 | N/A 7.205 in |

Locking Screws Quantity |

N/A 10 |

Locking Screws Size |

N/A M10 x 60 |

Ma-Locking Screws |

N/A 61 ft-lbs |

Hub Machining Tolerance |

N/A 0.002 in |

Shaft Machining Tolerance |

N/A -0.002 in |

Weight |

N/A 5.80 lb |

UPC Code |

N/A 044861076552 |

Downloads |

N/A

Catalog Page Installation & Removal Instructions Installation Demonstration (Video) Keyless Locking Technical Information |

- 1 Minimum hub outside diameter based on a Pressure reduction Factor of C=1.0 and hub material with tensile yield point = 45,000 psi for carbon steel and a tensile yield point = 30,000 psi for stainless steel. For details see Hub Strength in Technical Information.